-

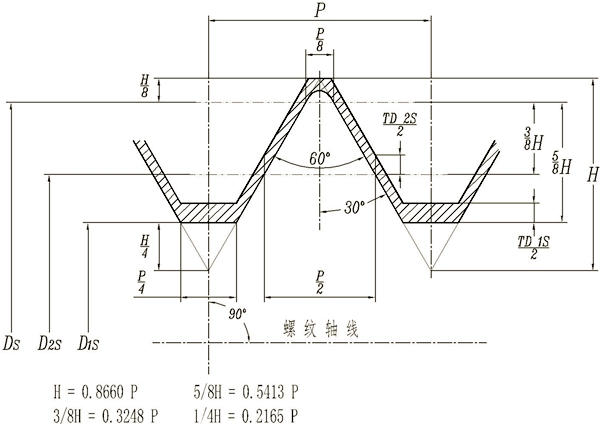

螺纹基本牙型尺寸和极限偏差

安装钢丝螺套后的

内螺纹

安装钢丝螺套后的内螺纹

大径 Ds

中径 D1s

小径 D1s

公称直径 D

mm

螺距 P

mm

公差带

基本尺寸

mm

极限偏差EI

μm

基本尺寸

mm

极限偏差 /μm

基本尺寸

mm

极限偏差 /μm

ES

EI

ES

EI

2

0.4

4H5H

2.52

0

2.26

+36

0

2.09

+90

0

5H

+51

6H

+70

+112

2.5

0.45

4H5H

3.08

2.793

+40

2.6

+100

5H

+55

6H

+75

+125

3

0.5

4H5H

3.65

3.325

+43

3.11

+112

5H

+60

6H

+80

+140

4

0.7

4H5H

4.91

4.454

+55

4.15

+140

5H

+75

6H

+98

+180

5

0.8

4H5H

6.04

5.519

+56

5.17

+160

5H

+76

6H

+101

+200

6

1

4H5H

7.3

6.649

+71

6.22

+190

5H

+94

6H

+126

+236

7

1

4H5H

8.3

7.649

+71

7.22

+190

5H

+94

6H

+126

+236

8

1.25

4H5H

9.62

8.812

+76

8.27

+212

5H

+101

6H

+136

+265

8

1

4H5H

9.3

8.649

+71

8.22

+190

5H

+94

6H

+126

+236

10

1.5

4H5H

11.95

10.975

+86

10.32

+236

5H

+114

6H

+154

+300

10

1.25

4H5H

11.62

10.912

+76

10.27

+212

5H

+101

6H

+136

+265

10

1

4H5H

11.3

10.649

+71

10.22

+190

5H

+94

6H

+126

+236

12

1.75

4H5H

14.27

13.136

+99

12.38

+265

5H

+134

6H

+174

+335

12

1.5

4H5H

13.95

12.975

+92

12.32

+236

5H

+124

6H

+164

+300

14

2

4H5H

16.6

15.299

+106

14.43

+300

5H

+144

6H

+186

+375

14

1.5

4H5H

15.95

14.975

+92

14.32

+236

5H

+124

6H

+164

+300

16

2

4H5H

18.6

17.299

+106

16.43

+300

5H

+144

6H

+186

+375

16

1.5

4H5H

17.95

16.975

+92

16.32

+236

5H

+124

6H

+164

+300

18

2.5

4H5H

21.25

19.624

+114

18.54

+355

5H

+154

6H

+198

+450

18

1.5

4H5H

19.95

18.975

+92

18.32

+236

5H

+124

6H

+164

+300

20

2.5

4H5H

23.25

21.624

+114

20.54

+355

5H

+154

6H

+198

+450

20

2

4H5H

22.6

21.299

+106

20.43

+300

5H

+144

6H

+186

+375

20

1.5

4H5H

21.95

20.975

+92

20.32

+236

5H

+124

6H

+164

+300

22

2.5

4H5H

25.25

23.624

+114

20.54

+355

5H

+154

6H

+198

+450

22

2

4H5H

24.6

23.299

+106

22.43

+300

5H

+144

6H

+186

+375

22

1.5

4H5H

23.95

22.975

+92

22.32

+236

5H

+124

6H

+164

+300

24

3

4H5H

27.9

25.948

+144

24.65

+400

5H

+186

6H

+239

+500

24

2

4H5H

26.6

25.299

+114

24.43

+300

5H

+154

6H

+198

+375

24

1.5

4H5H

25.95

24.975

+99

24.32

+236

5H

+134

6H

+174

+300

27

3

4H5H

30.9

28.948

+144

27.65

+400

5H

+136

6H

+239

+500

27

2

4H5H

29.6

28.299

+114

27.43

+300

5H

+154

6H

+193

+375

27

1.5

4H5H

28.95

27.975

+99

27.32

+236

5H

+134

6H

+174

+300

30

3.5

4H5H

34.55

32.274

+154

30.76

+450

5H

+198

6H

+254

+560

30

2

4H5H

32.6

31.299

+114

30.43

+300

5H

+154

6H

+198

+375

30

1.5

4H5H

31.95

30.975

+99

30.32

+236

5H

+134

6H

+174

+300

33

3.5

4H5H

37.55

35.274

+154

33.76

+450

5H

+198

6H

+254

+560

33

2

4H5H

35.6

34.299

+114

33.43

+300

5H

+154

6H

+198

+375

33

1.5

4H5H

34.95

33.975

+99

32.32

+236

5H

+134

6H

+174

+300

33

4

4H5H

41.2

38.598

+164

36.87

+475

5H

+210

6H

+274

+600

36

3

4H5H

29.9

37.948

+144

36.65

+400

5H

+186

6H

+239

+500

36

2

4H5H

38.6

37.299

+114

36.43

+300

5H

+154

6H

+198

+375

39

4

4H5H

44.2

41.598

+164

39.87

+475

5H

+210

6H

+274

+600

39

3

4H5H

42.9

40.948

+144

39.65

+400

5H

+186

6H

+239

+500

39

2

4H5H

41.6

40.299

+114

39.43

+300

5H

+154

6H

+198

+375

更多相关数据

|

安装钢丝螺套用内螺纹 |